Geoprobe® Services

Geoprobe Drilling

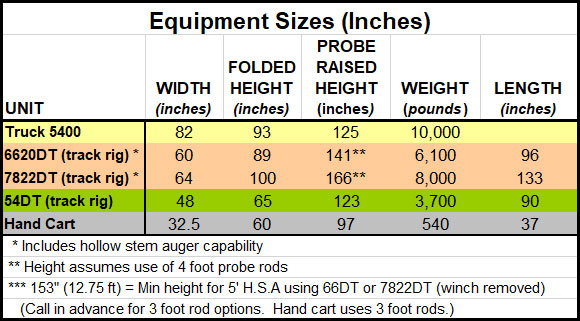

DIRECT PUSH ANALYTICAL HAS SEVERAL DIFFERENT GEOPROBE DRILL RIGS AVAILABLE:

- (2) Geoprobe® 5400 truck mounted units in 4-wheel drive trucks

- (2) Geoprobe® 54DT Track mounted units

- (1) Geoprobe® 4200 Hand Cart Mounted unit, with external hydraulic pump

- (1) Geoprobe® 66DT track mounted unit with auger capabilities

- Geoprobe® 6620DT & 7822DT track mounted units with auger capabilities, available as needed

- The Geoprobe® mounted on a hand cart (i.e. dolly) can access entranceways which are regular man-door width.

*All the Geoprobe® units can install 3/4 or 1 inch diameter wells through the tooling. Additionally, 66 Series (and higher) Series track units are capable of turning 4.25-inch ID augers, as well as use direct push technology for setting up to two-inch diameter wells.

Get a free quote

Other services

- Concrete Coring

- Direct Sensing

- Geophysical Contaminant Logging

- Geologist Field Support Services

- Groundwater Sampling

- GROUNDWATER VERTICAL PROFILING

- High Resolution Site Characterization

- Mobile Lab Services

- Monitoring Well Installation & Abandonment Services

- PFAS & PFOA Sampling

- Public & Private Utility Location Coordination

- Soil Sampling

- Soil Gas Sampling

- Site Visits

- Sub-Slab Soil Gas Sampling

- Vapor Intrusion

DUAL TUBE TOOLING

Dual tube tooling is also particularly useful in that it allows for the installation of temporary or permanent PVC well material for collection of groundwater samples after the soil samples have been collected. The dual tube system prevents natural formation collapse that you would have if using the macro-core system for soil sampling. A groundwater sample can easily be obtained from the PVC with poly tubing equipped with a check valve and/or peristaltic pump. Dual Tube provides the sample integrity one would achieve sampling through hollow stem augers, however, sample collection is achieved much quicker. We can provide literature, which describes dual tube sampling (2.25-inch diameter used with the 5400 Models and 3.25-inch diameter available with the 66DT Model) in greater detail, or you can visit www.geoprobe.com. Direct Push Analytical Corp. operates only Geoprobe® tooling and equipment because we believe that Geoprobe® is the industry leader.